boards. The interior of the body shell and

Attachments shall neither interfere with

the side reinforcements shall be welded

nor obstruct chassis components.

with continuous welds. The top rail, sides

3.5.4

TYPE IV (DUMP).

and tailgate shall be completely boxed

Type IV vehicles shall have a hydraulic

and continuously welded. The body shall

hoist operated dump body.

A rear

have sloping running boards and sloping

bumper is not required. Unless otherwise

horizontal tailgate braces to minimize the

specified by option code, the body shall

buildup of dirt. Wiring harness across the

have dimensions and level capacity of not

rear apron shall be enclosed in conduit or

less than that specified per the Standard

polyethylene loom except at terminal ends

Item Number.

and shall be secured by hangers to the

under body floor, on not more than 12

3.5.4.1 DUMP BODY CONSTRUCTION.

inch centers.

Body sides and front head shall be

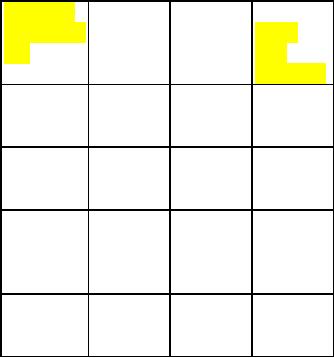

Figure VII - TYPE IV Dump Truck

constructed from not less than 8 gauge

Requirements

(4.176 mm) (0.1644 in) A570 (50,000 psi

Capacity 6.1/ 8

7.6/ 10 9.2/ 12

yield strength) steel. Body floor shall be

3

(m / cu.

Code

no less than 1/4 inch AR235, (100,000 psi

yd)

B15

yield strength) steel. The front head shall

=11.5/15

be capable of withstanding a horizontal

3960/144 4270/168 4570/180

Body

static loan equal to one-half the payload

Length

capacity of the vehicle without permanent

(mm / in.)

distortion. When body floor is constructed

Number 11

13

14

in two or more pieces, a continuous seam

of cross

weld having full penetration shall be

members

provided. Full length, formed rub rails of

Vertical

4

5

5

minimum width to cover rear dual tire

brace per

treads shall be provided. Triangular or

side,

if

box-section side braces, of the minimum

provided

width quantities specified in Figure VII for

Horizontal 1

1

1

the respective body length and vehicle

braces

classes, shall be constructed of not less

per side

than 8 gauge (4.176 mm) (0.1644 in)

steel. One horizontal brace (per side)

running the entire length of the body, tied

3.5.4.2

CAB PROTECTOR.

into the front and rear corner pillars is

A cab protector shall be attached to the

acceptable in lieu of vertical braces. They

front end of the body. The cab protector

shall be sloped and continuously welded

shall extend the full width of the cab. The

or formed into each side of the body.

cab protector shall extend not less than

Side braces shall be equally spaced on

1020 mm (40 inches) forward from the

each side of the body, between the head

front of the dump body. The cab protector

sheet and full box type rear corner posts,

shall be not less than 8 gage (4.176 mm)

and welded to body side plates. Front

steel or 10 gage (3.416 mm) (0.1345 inch)

head sheet shall be formed or reinforced

high tensile, 345 MPa (50,000 psi) yield

for rigidity. Head sheet and tailgate shall

strength steel. The cab protector shall be

be not less than 200 mm (8 in) higher

capable of supporting an evenly

than the sides. Sides shall have pockets

distributed load of not less than 910 kg

provided at each end for insertion of side

(2,000 pounds). The cab protector is not

Federal Standard 807M

Page 26 of 65

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business