MIL-DTL-62034G(AT)

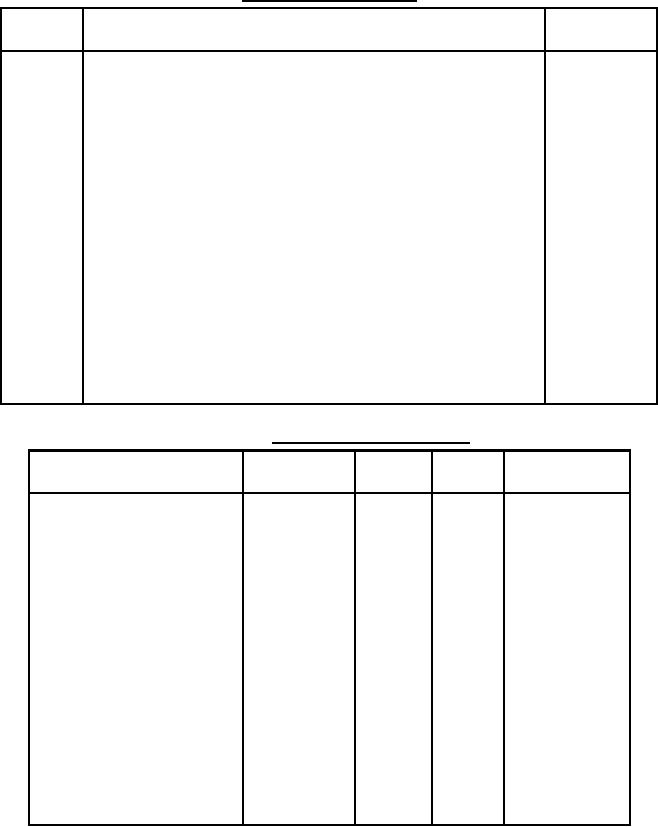

TABLE IV. Classification of defects - Continued.

Method of

Category

Defect

examination

203

Electrical system components improper installation or

Visual

assembly (see 3.3.2).

204

Battery cables improper installation, wrong lengths

Visual

(see 3.4.10.2).

205

Refrigeration unit, damaged; leaks (see 3.4.10.2).

Visual

206

Bumper, lifting eyes and tiedowns, missing; improperly

Visual

located; welding defects (see 3.6.1).

207

Lubrication fittings, defective; missing; improper installation

Visual

(see 3.7).

208

Lubrication, improper (see 3.7).

Visual

209

Servicing, adjustment improper (see 3.7).

Visual

210

Faulty workmanship not affecting performance (see 3.8).

Visual

211

Decal markings, data and instruction plates, incomplete data;

Visual

missing; improper location or size (see 3.9).

212

Paint, application or color improper (see 3.10).

Visual

213

Protective coatings, application, coverage or materials

Visual

improper (see 3.10).

TABLE V. Classification of inspection.

First

Title

Requirement

Test

Conformance

article

Environmental

3.4.1

4.5.3

X

Highway & cross-country

3.4.2

4.5.4

X

Service brake

3.4.3.1

4.5.5

X

X

Automatic actuation

3.4.3.2

4.5.6

X

X

device

Fording

3.4.4

4.5.7

X

Tracking ability

3.4.5

4.5.8

X

X

Turning ability

3.4.6

4.5.9

X

Landing gear

3.4.7

4.5.10

X

Gradeability

3.4.8

4.5.11

X

Electromagnetic

3.4.9

4.5.12

X

compatibility

Waterproofing & sealing

3.4.10.1

4.5.13

X

X

Heat leakage

3.4.10.2.1

4.5.14

X

Floorpan waterproofness

3.4.10.2.2

4.5.15

X

Durability

3.4.11

4.5.16

X

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business