MIL-DTL-45150L

3.5.2.2 Operation without payload. The 6000 mile durability test shall include 50 miles of

gravel and 30 miles of Belgian block without payload, at start and completion of foregoing

operations, for a total of 160 miles (see 4.8.2).

3.5.3 Safety standards. No condition shall exist which may create a safety hazard to

operating or maintenance personnel (see 4.8.3).

3.5.4 Servicing and adjustments. The trailer shall be adjusted and serviced for each

chassis for immediate operational use, including at least the following: adjust braking system,

check electrical system, inflate all tires, and completely lubricate the trailer and all running gear

with grades of lubricants recommended in table III for the ambient temperature at the delivery

point (see 4.5 and 4.6).

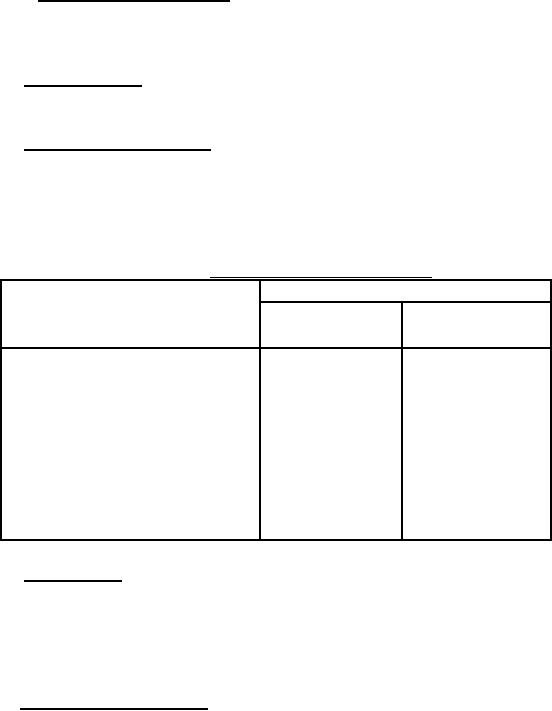

TABLE III. Service products specifications.

Ambient air temperature

-65° to 0°F

-10° to +115°F

(-54° to -18°C)

(-23° to 46°C)

Product use

Oil:

For hydraulic brakes

MIL-B-46176

MIL-B-46176

For shock absorbers

MIL-PRF-6083

MIL-PRF-6083

For general purpose lubrication

Commercial

MIL-PRF-3150

Grease:

For sealed bearings

MIL-G-23827

MIL-G-23827

For general chassis lubrication,

MIL-PRF-10924

MIL-PRF-10924

including wheel bearings

3.5.5 Surface finish. The vehicle component assemblies shall be cleaned, treated, and

painted in accordance with the manufacturers standard practices (see 4.5). The paint top coat

color shall be as specified in the contract or order (see 6.2). If chemical agent resistant coating

(CARC) is required, it shall be specified in the contract or order (see 6.2). When specified

(see 6.2), camouflage pattern shall conform to the pattern specified.

3.5.6 Identification and marking. Identification and marking shall be permanent and

legible and shall include:

a. Chassis model number

b. Manufacturer's identification

c. Part or identifying number (PIN)

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business