MIL-PRF-62272C(AT)

3.2.1 Payloads. The semitrailer shall be capable of transporting 45 000 lb (20 400 kg) of

breakbulk cargo uniformly distributed over the deck and any combination of containers and

shelters as listed in table II, without permanent deformation of the frame while operating at the

speeds and terrain profile as specified in table I. The 20-ft ( 6.1 m) container, with loadings as

specified in table II, shall be located on the semitrailer (see 4.5.1).

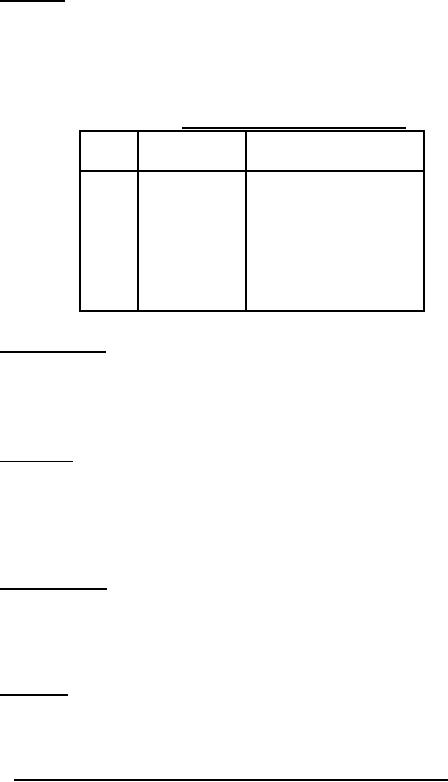

TABLE II. Payload containers and shelters.

Length

Weight

Qty

ft

(cm)

lb

(kg)

1

20

(610)

44 800

(20 300)

2 or 1

10

(305)

total 44 800

(20 300)

each 22 400

(10 200)

3

6-2/3

(203)

total 44 800

(20 300)

each 14 933

(6700)

4

5

(107)

total 44 800

(20 300)

each 11 200

(5100)

3.2.2 Environmental. The semitrailer shall be capable of operating in ambient

temperatures ranging from minus (-) 40 degrees Fahrenheit (°F) [-32 degrees Celsius (°C)] at

1200 ft in altitude to plus (+) 125°F (52°C) at -500 ft in altitude. The semitrailer shall also be

capable of being stored in temperatures up to 160°F (71°C) (see 4.6).

3.2.3 Durability. The semitrailer shall demonstrate a 0.75 probability with 0.5 confidence

of completing 12 000 mi. (19 300 km) without replacement or overhaul of the major components

and subassemblies; that is frame, body, platform, suspension assembly including axles and wheels

less tires, landing gear, major brake system components less brake shoes, and common hardware

(see 4.5.1).

3.2.4 Maintainability. Total maintenance time, total scheduled and unscheduled

maintenance excluding driver and crew checks and services, shall be no more than 30 manhours

during 12 000 mi. (19 300 km). This equates to a maintenance ratio (MR) not greater than

0.0025 maintenance manhours per operating mile (see 4.5.1).

3.2.5 Materials. Materials used shall be in accordance with the manufacturer's materials

specifications for this type of item. The materials shall be free from defects which adversely affect

appearance, performance or serviceability of the finished product (see 4.5.1).

3.2.5.1 Recycled, recovered, or environmentally preferable materials. Recycled,

recovered, or environmentally preferable materials should be used to the maximum extent possible

provided that the material meets or exceeds the operational and maintenance requirements, and

promotes economically advantageous life cycle costs.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business