MIL-DTL-13714F

4.5 Conformance inspection.

4.5.1 Inspection provisions.

4.5.1.1 Lot size. An inspection lot shall consist of all vehicles from an identifiable

production period (one day's production), submitted at one time for examination and test.

4.5.1.2 Sampling for inspection. A sample shall be selected from each inspection lot in

accordance with ASQC/ANSI Z1.4.

4.5.2 Examination. Visual, dimensional, and primary functional examination shall consist

of examination of the vehicle for conformance to the applicable drawings and this specification.

Examinations shall be performed against the classification of defects specified in table IV. The

following constitutes a part of the classification of defects (see 6.3):

a. Any weep constitutes a minor defect.

b. Any seep constitutes a minor defect.

c. Any drip constitutes a major defect when the vehicle has been standing idle and

the components are at ambient temperature.

d. Any droplet that occurs at a static fit, metal to metal, or gasket to gasket

combination shall constitute a major defect.

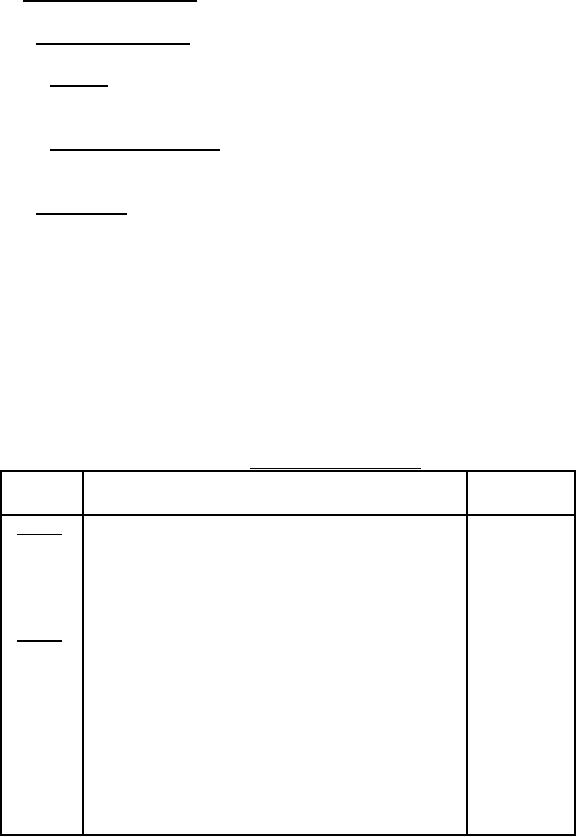

TABLE IV. Classification of defects.

Method of

Category

Defect

examination

Major:

101

Landing device not as specified (see 3.4.6).

Visual

102

Fording not as specified (see 3.4.7).

Visual

103

Lifting transportability not as specified (see 3.4.8).

Visual

Minor:

201

Lights not as specified (see 3.3.3).

Visual and

functional

202

Safety not as specified (see 3.3.5).

Visual

203

Painting not as specified (see 3.6.1).

Visual

204

Rustproofing not as specified (see 3.6.2).

Visual

205

Identification marking not as specified (see 3.6.3). Visual

206

Servicing and adjustment not as specified (see 3.7). Visual and

functional

207

Workmanship not as specified (see 3.8).

Visual

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business